Roof sandwich panels are used as roofing material for production buildings, industrial halls, storage facilities, shopping centers, large-scale stores, sports facilities, livestock buildings, and increasingly they are used in residential construction.

We offer you the highest quality laminated roofing panels that are very easy and quick to install, and their use ensures the tightness of the structure and, above all, very good insulation. All our roof panels consist of structural and insulating core and outer layers made of steel sheet.

TYPES OF ROOF SANDWICH PANELS

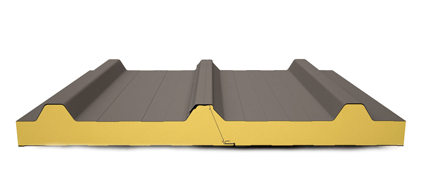

Due to the different core materials, our range of roofing panels is divided into standard roofing and PUR / PIR roofing panels. Standard panels include polystyrene or mineral wool core, while PUR / PIR boards have polyurethane or polyisocyanurate core (both of which belong to the polyurethane family).

The basic function of the layered roofing panels is the thermal insulation of roofs, the sealing of the structure, as well as the insulation of ceilings and floors. Very popular are roof solutions using PUR and PIR sandwich panels. Their main task is the thermal insulation of flat roofs made of steel sheets or with concrete or wood base. These types of roofs are most often encountered in large buildings, e.g. industrial halls or commercial buildings. Roof plates with PUR foam core also apply to the insulation of the attic of residential buildings. In contrast, PIR foam, which is also used as the core of the sandwich panel, apart from hardness and very good thermal insulation properties, is characterized by significantly higher fire resistance. Speaking of roofs, this is a very important aspect because in the event of a fire, the structure will last much longer and the roof will not collapse immediately, thus giving you time to evacuate. However, the overall fire resistance is distinguished by the core of mineral wool. Therefore, if you require increased fire resistance, you may want to use roofing panels with mineral wool core. On the other hand, sandwich panels with polystyrene core are very economical solution for roofing.

ROOF PLATE STANDARD

PUR / PIR ROOF PLATE

COLORING ROOF PANELS

The roofing panels we offer are available in RAL colors. However, due to the influence of sunlight and the heating of the roof surface, most roof tiles are produced in white. Thanks to the use of white plates and thus avoiding strong heating of the surface, the effects of thermal expansion of the material are minimized, which directly affects the durability of the roofing.

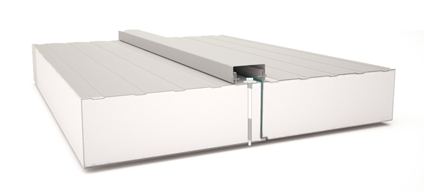

CONNECTING ROOF SANDWICH PANELS

Layered roof panels are equipped with a one-sided modified locking plate. From the inside of the plate is the same lock as the wall plate, while on the outside of the plate is the tongue projection at an angle of 90 degrees with respect to the plate plane. The panels are connected by a galvanized u-shaped fastener at the place of fixing the sandwich panels to the structure. The use of masking treatment can hide the connection of the roofing panels and increase the tightness of the link.

Technical parameters of roof sandwich panels

| Plate roofing | |||

|---|---|---|---|

| Type of core | styrofoam | polyurethane | mineral wool |

| Thickness of plate [mm] | 40-250 | 40-100 | 40-150 |

| Weight [kg] | 8,46-11,9 | 10,5-12,9 | 15,5-25,9 |

| Factor U [W/m2K] | 0,70-0,15 | 0,50-0,22 | 0,66-0,28 |

| Maximum length [m] | 16 | 18 | 12 |

| Overall width [mm] | 1220 | 1020 | 1220 |

| System width [mm] | 1200 | 1000 | 1200 |

| Cladding thickness [mm] | 0,5 | 0,5 | 0,5 |